Write something

How does your shop stack up?

I was asked recently by a podcast host what technicians should look for when searching for a shop. I answered off the cuff with what I've seen over the years that separates the shops that really take care of their employees from those who don't. I thought it was a pretty good answer in the moment but the question nagged at me long after the interview. So I teamed up with my buddy ChatGPT and ran some prompts to find out what the common threads are between the shops we've worked with that hire faster and retain longer. Then I compiled them together into a checklist for technicians (see below). How does your shop stak up with my list? Am I on the mark or totally off-base? Would love to get your feedback. ___________________________________________________________________________________________________ Technician's Checklist for Identifying a Good Auto Repair Shop to Work For: 1. Company Culture & Values - Prioritizes culture-fit when hiring. - Demonstrates clear mission and core values emphasizing integrity, communication, and teamwork. - Environment encourages positive attitude, open communication, and mutual support. 2. Leadership & Management - Owner or management has direct industry experience as technicians. - Management maintains an open-door policy for employees. - Regular, structured feedback meetings between management and employees (e.g., quarterly goals meetings, daily huddles and 1-on-1's). 3. Work Environment - Well-equipped, Modern facilities with necessary diagnostic tools and equipment. - Access to comprehensive resources, including tools, laptops/tablets, diagnostic software, and digital inspection processes. - Shop promotes efficiency and organized workflow to minimize downtime and maximize earning potential. 4. Training & Development - Strong emphasis on ongoing training and professional development (ASE certifications encouraged and incentivized). - Clearly defined apprenticeship or mentorship programs. - Opportunities to attend industry-specific training courses and certifications, often employer-paid.

I asked over 100 techs why they quit. Here’s the pattern.

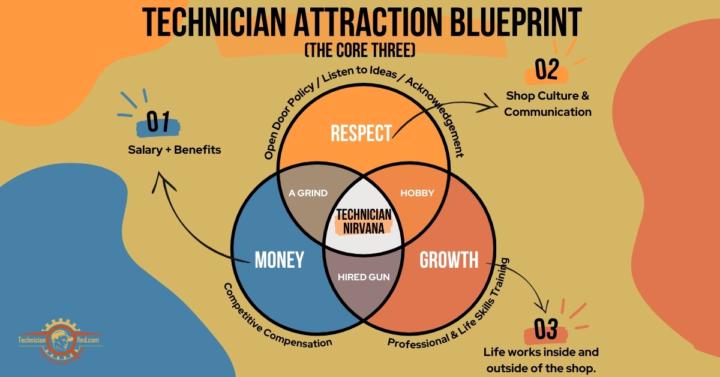

As an industry, we keep saying we’re “short on techs,” but the best ones aren’t hiding—they’re just ignoring shops that look the same. After 7 years of conversations and 100+ exit interviews, the pattern is blunt: 1) Wrong pond, wrong bait.We blast generic job-board ads and expect top performers to bite. They don’t. They move through referrals, reputation, and communities where your shop rarely shows up. 2) Leaving beats staying (on paper). Great techs flirt with opening a shop not because they want payroll headaches, but because it promises three things they’re missing: respect, control over income, and real growth. 3) The 3-circle gap (why they quit): - Respect: Real open-door policy, not lip service. Clear communication, decisions with tech input. - Money: Competitive comp that tracks value, not tenure. Transparent paths to higher earnings. - Growth: Personal AND Professional training, tooling, and a ladder beyond “turn more hours”. Great employees want to go with shops that want their life to work inside and outside of the shop. When all three circles overlap, two things happen fast: - Retention sticks. People stop taking recruiter calls. - Attraction turns magnetic. You stop “hiring” and start selecting. The “shortage” mostly exists in shops trying to win with one circle (usually Money) and hoping the rest will sort itself out. If you want fewer resignations this quarter, start here: audit your Respect–Money–Growth overlap. Then replace job-board spam with proof—tech-facing videos, team-led referrals, and visible systems that make great techs say, “Yep, I can thrive there.” The future isn’t about convincing kids to join the industry—it’s about building shops worth joining.

He was about to lose his 3 best techs (until he tried this Monday morning ritual)

Yesterday I heard a story from a client that I had to share. Mike, a shop owner from Dallas called his business coach in a panic. "I just found out through the grapevine that THREE of my best techs are looking at other shops," he said. "One already has an offer. I had no idea they were unhappy." Sound familiar? Here's the kicker: All three techs had been with Mike for 5+ years. They weren't leaving for money. They were leaving because of something Mike never saw coming - they felt invisible. One tech later told him: "You talk to me when something's broken or when I mess up. But you never ask how I'm doing or what would make my job better." Ouch. LESSON: Mike learned something that changed everything: Exit interviews are autopsies. By then, your tech is already gone. What he needed were "Stay Interviews" - proactive, 10-minute weekly conversations that catch problems while you can still fix them. Here's the exact system Mike implemented (that kept all 3 techs from leaving): The Monday Morning Stay Interview Process Step 1: The 3-Question Check-In (5 minutes) Every Monday, Mike asks each of his top techs: 1. "What's one thing that went well for you last week?" 2. "What's one frustration you're dealing with right now?" 3. "If you could change one thing about your job this week, what would it be?" Step 2: The Early Warning Scorecard (2 minutes) Mike tracks these 5 flight-risk indicators weekly: - Energy level (1-10) - Tool/equipment complaints - Customer and team interactions and overall mood - Initiative on jobs (taking on challenges vs. bare minimum) - Water cooler talk (engaged vs. withdrawn) Any score dropping 2+ points = immediate deeper conversation Step 3: The Fix-It Promise (3 minutes) Mike commits to addressing ONE issue each week - even small ones. - Week 1: Fixed the shop fan that had been broken for 6 months - Week 2: Changed the parts ordering process that was driving everyone crazy - Week 3: Started rotating who gets the gravy jobs

I was wrong about tool guys.

For years, I've been telling shop owners that "chatting up the tool guy" for tech leads was a dying strategy. Tool dealers are getting bombarded from every angle—everyone wants the same thing: "Know any good techs?" It's exhausting for them. And frankly, ineffective for you. But here's what I missed... I was talking to a shop owner today and she shared a story that flipped my perspective: Her A-tech was quietly job hunting and asked the tool guy for a reference letter to land a dealer position. But here's the twist—because this owner had built a REAL relationship with his tool guy (not just the "got any leads?" variety), the tool guy gave her a heads up. Result? The owner got ahead of it. Invited the tech for a conversation. Countered the offer. The tech is young and frankly in my opinion needs to learn a lesson, so he decided to leave anyway but it was better that it wasn't totally out of the blue. That heads up gave the shop owner a bit more time to prepare so they weren't caught totally flat-footed. The lesson hit me like a torque wrench to the head: Stop treating tool guys as tech vending machines. ❌ Start treating them as your shop's early warning system. ✅ Think about it: - They're in EVERY bay - They hear EVERY conversation - They know who's happy, who's looking, who's checked out - They're neutral territory—techs trust them Your tool guy isn't your recruiter. They're your intelligence network. The strongest shops don't just buy tools from these folks. They build genuine relationships that create a protective moat around their talent. So here's my revised stance: - Asking tool guys for tech leads? Still not great. - Building real relationships with them? Absolutely golden. The difference? One is transactional. The other is transformational. What's your take? How has your relationship with tool dealers impacted your retention? Drop your thoughts below. 👇

Trust isn't optional — it's the fuel for high-performing teams

Here are 3 proven ways to build unbreakable trust with your employees (that most shop owners completely miss): 1️⃣ Share the WHOLE Story - Your team can't trust you if you only share the wins. They need the real picture — including the challenges. Action step: In your next team meeting, openly share one challenge the shop is facing. Watch how transparency transforms trust. 2️⃣ Keep the Small Promises - It's not the big commitments that break trust — it's the small ones you miss. That oil filter you said you'd order? That schedule you promised to post? Action step: When you say "I'll send that over," do it within 24 hours. No exceptions. Small follow-through = massive trust. 3️⃣ Make Feedback a Daily Habit - High-trust teams give and receive feedback without fear. It's how they get better, faster. Action step: Add a 2-minute "Feedback + Shoutout" to your daily huddle. One improvement, one recognition. Every. Single. Day. The trust test: Would your team say they trust each other — and trust YOU? Drop a comment: Which of these will you implement first? 👇

1-30 of 38

skool.com/technicianfind

Proven templates, strategies, training and top-level networking to help independent auto repair shops hire quality staff faster.

Powered by