Write something

Tickets: A measure Qualified or Competent

I'd love to hear from the group. Now the majority of this page its discussed about how the industry has slipped a little due to the introduction of college certed individuals policing and policies an electrical industry they dont fully understand. My question is- If "John Lineman" has his ticket was verifiably trained (Apprenticeship + records+ curriculum+ Verified On the job hours) is he Qualified or Competent.. *Osha says anyone checking those boxes of verified training metrics and the knowledge checks is deemed qualified.... NOW, We take "Bill the MFJL" Whoms paper trail includes Groundhand/Operator for 5+ years -insert magic wave of a wand-- POOF Bill is a JL and companies dont verify <Compliance to training regulations, History of individual, no knowledge checks> TEST QUESTION IS: ONLY select one. Is Bill in the above Paragraph? A) Qualified B) Competent C) Both A and B D) Someone who bought their ticket and should have an *** placed beside their name and not allowed Apprentice training privileges until all criteria of training and proof of On the Job competency being met along with knowledge checks. We worry about our industry rightfully so. Many of us this is what we know. We love it to the fullest maybe to strong. Shamefully the answer above is most often wrong. Safety departments isn't the only cog in the machine with a tooth missing. I now know 8+ individuals that are either crew leds or General Foreman or daily MFJLs that did not pull one day outside of pulling levers on a digger or excavator or shoveling or running a hand line. Curious is all 🤙 Daniel Cooper, CUSP,CSP

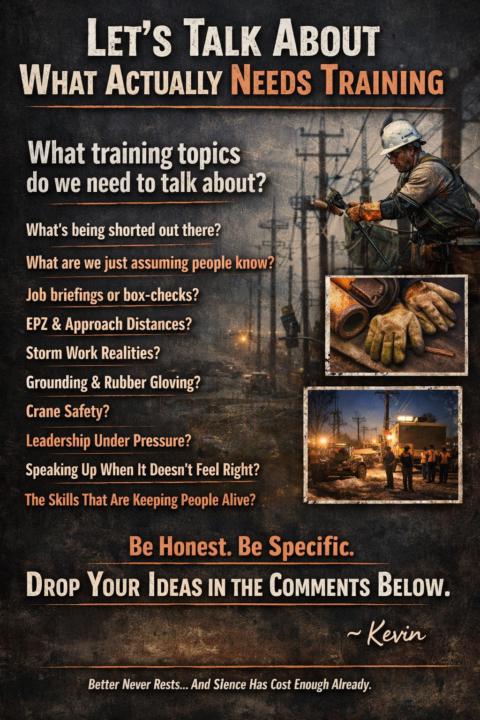

Let’s Talk About What Actually Needs Training

I’ve spent the last year saying a lot of things out loud that this trade usually keeps quiet. Calling out gaps. Calling out theater. Calling out the difference between “we trained them” and “we prepared them.” Now I want to turn the floor over to the people who live in the arena. Not corporate checklists. Not polished slide decks. Not whatever topic happens to look good on a quarterly report. I want to hear from you. What areas of training do we need to be talking about that we’re not? Where are new hands getting shorted? Where are seasoned hands being expected to “just know” without anyone actually teaching it anymore? Is it job briefings that have turned into a box-check? Is it EPZ and approach distances getting watered down? Is it storm work realities versus what the policy says? Is it switching. Grounding. Rubber use. Crane safety. Leadership. Decision-making under pressure. Speaking up when something doesn’t feel right. Or the quiet skills that keep people alive long after the class ends? Be honest. Be specific. Be uncomfortable if you need to be. This page isn’t here to protect egos. It isn’t here to make anyone look good. And it damn sure isn’t here to repeat the same recycled content we’ve all sat through a hundred times. If we’re going to talk about training, let’s talk about what actually matters…What’s failing people in the field…What keeps showing up in close calls, near misses, and funerals. Drop it in the comments. One topic or ten. Technical. Cultural. Leadership. Personal. If it’s real, it belongs in the conversation. Better never rests…and silence has cost this trade enough already. ~Kevin

SAFETY SUNDAY — JANUARY 2026

The first Safety Sunday of a new year always feels different. Quieter. Heavier. More honest. Because whatever we didn’t fix last year followed us into this one. 2026 didn’t reset the scoreboard. It didn’t erase bad habits. It didn’t magically turn weak leadership into strong leadership or sloppy thinking into discipline. All it did was hand us another year in the arena. And here’s the truth most people won’t say out loud… If we keep doing safety the same way, 2026 will take the same names 2025 did. I’m done pretending safety is a program. Programs end. Posters fade. Slogans get recycled. The work doesn’t. Safety is what shows up when nobody’s watching. It’s what you say when the plan is wrong and the pressure is high. It’s whether you’re willing to be uncomfortable now instead of attending a funeral later. And that choice is made long before the job starts. Somewhere along the way, we let safety drift away from the field and into conference rooms. We turned it into metrics, optics, and talking points. We rewarded quiet compliance instead of hard questions. We taught people how to pass audits instead of how to survive work. And then we act surprised when experience gets overridden by urgency… when apprentices don’t speak up… when journeymen stop fighting bad calls… when near misses get buried because they’re “bad for morale.” That’s not safety. That’s silence dressed up as progress. Here’s the line I’m drawing to start 2026… If safety only exists when it’s convenient, it doesn’t exist at all. If a man or woman can’t stop work without fear of retaliation, your culture is broken. If production pressure always wins, your priorities are exposed. If leadership never feels discomfort, it’s being absorbed by the field. And the field always pays first. This year, I’m not interested in perfect language or polished delivery. I care about focused minds. Clear boundaries. Honest conversations. Plans that respect physics instead of challenging it. I care about whether the newest hand on the crew feels protected enough to speak… and whether the most seasoned hand feels respected enough to be heard.

1-16 of 16

skool.com/lineman-bullshit

Where the boots speak truth. Grit, real talk, hard lessons, no corporate gloss. Lineman Bull$hit™—the trade, unfiltered.

Powered by