Activity

Mon

Wed

Fri

Sun

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

What is this?

Less

More

Owned by Jd

Quality Professionals learning Six Sigma, Lean, AS9100, and other topics

Memberships

MM

Manufacturing Masterclass

3 members • $169/m

MotoFab Welding SKOOL

82 members • Free

Skoolers

174.8k members • Free

3 contributions to MotoFab Welding SKOOL

R33 GTR Manifold Failure

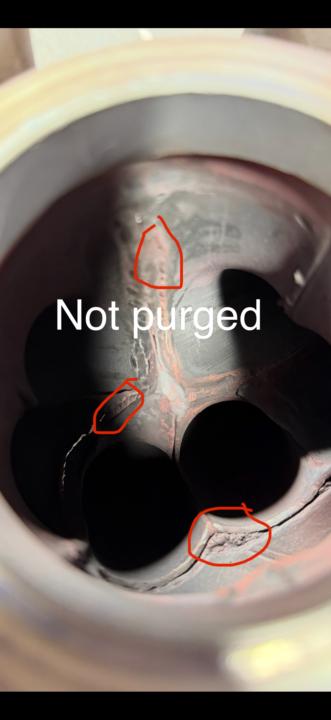

This is a manifold for an R33 GTR sent to me by a customer for me to build him a new manifold, videos on that coming soon. I am going to break down the weld defects and why they cause failure. 1. Undercut - Undercut is the gouge at the edges of the weld, undercut happens from the puddle or the part getting too hot and pulling too much material from the base metal into the puddle. This can be avoided by keeping the part and puddle from overheating and by adding enough filler rod. Undercut causes weakness by thinning out the base material and creating a point that is vulnerable to stress. 2.No purge - Not purging stainless steel causes a few issues, the first is lack of fusion, the puddle when it penetrates through the material is not able to fully melt the part together because it is exposed to oxygen on the other side and oxidizes before it can fuse. The second problem is that the rough chromium carbide precipitation also known as “sugar” can break off and enter the turbocharger causing damage. It also is not ideal for flow to have a rough lumpy surface. 3. Lack of penetration, in the 4th photo you can see the weld looks ok and has no undercut. When a weld cracks at the edge it is due to undercut or lack of fusion to the base metal. In the case the weld cracked in the center because it was run cold without enough penetration meaning that the overall thickness of the weld material was much thinner and weaker than the base metal.

Crappy weld on a chair

Hey wanted to know what defects you all can find on this chair handle. It came off of one of the bar stood at my in-laws place and wanted to know your thoughts on the weld.

Hello

My name is JD. I’m not a welder but I am an inspector for a CNC shop which has a sheet metal and fabrication cell. I am the primary inspector for that cell so I want to get better at understand different welds and how to inspect them. What is a good weld and what is 💩

0 likes • Aug 22

@Grant Pratt What are undercuts and fish eyes? To be honest regarding welding, the only industry we don't seem to do a lot of welding is aerospace, which is funny considering everything else in the shop is almost exclusively that. But the welding seems to primarily be medical or atheistic covers for different industries.

1-3 of 3

@jd-jessop-7290

Machine shop Quality Inspector, I give back and help others learn things used on the job in manufacturing.

Join my skool! See my groups below

Active 1h ago

Joined Aug 21, 2025

INTJ