Write something

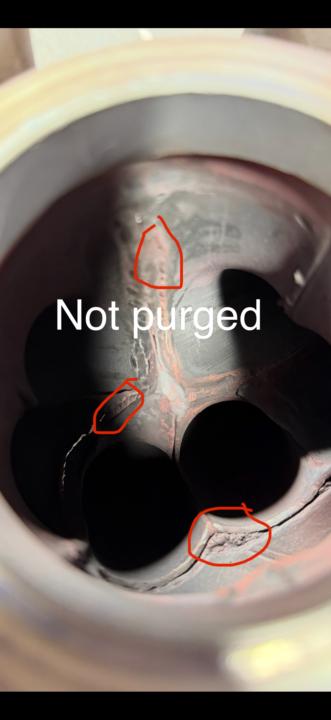

R33 GTR Manifold Failure

This is a manifold for an R33 GTR sent to me by a customer for me to build him a new manifold, videos on that coming soon. I am going to break down the weld defects and why they cause failure. 1. Undercut - Undercut is the gouge at the edges of the weld, undercut happens from the puddle or the part getting too hot and pulling too much material from the base metal into the puddle. This can be avoided by keeping the part and puddle from overheating and by adding enough filler rod. Undercut causes weakness by thinning out the base material and creating a point that is vulnerable to stress. 2.No purge - Not purging stainless steel causes a few issues, the first is lack of fusion, the puddle when it penetrates through the material is not able to fully melt the part together because it is exposed to oxygen on the other side and oxidizes before it can fuse. The second problem is that the rough chromium carbide precipitation also known as “sugar” can break off and enter the turbocharger causing damage. It also is not ideal for flow to have a rough lumpy surface. 3. Lack of penetration, in the 4th photo you can see the weld looks ok and has no undercut. When a weld cracks at the edge it is due to undercut or lack of fusion to the base metal. In the case the weld cracked in the center because it was run cold without enough penetration meaning that the overall thickness of the weld material was much thinner and weaker than the base metal.

Dodge viper header hacking!

I hate doing work like this, it is not to my typical quality standard but I am working on getting the 8.0L Viper V10 test fitted into the 73 dodge charger and his is what must be done temporarily. 3” 304 stainless Vband to very old and dirty mild steel even after cleaning. 309 3/32 rod to help with the gaps. This header was made by hand in the dodge factory so it is nowhere near round where we cut it.

How to Weld SCH 10 stainless steel!

https://youtu.be/HKfY5NUWDGw?si=MBI2nZFhspeSUoLy

Torch angle sch10

Why do so many have such an extreme Torch angle when welding sch10?

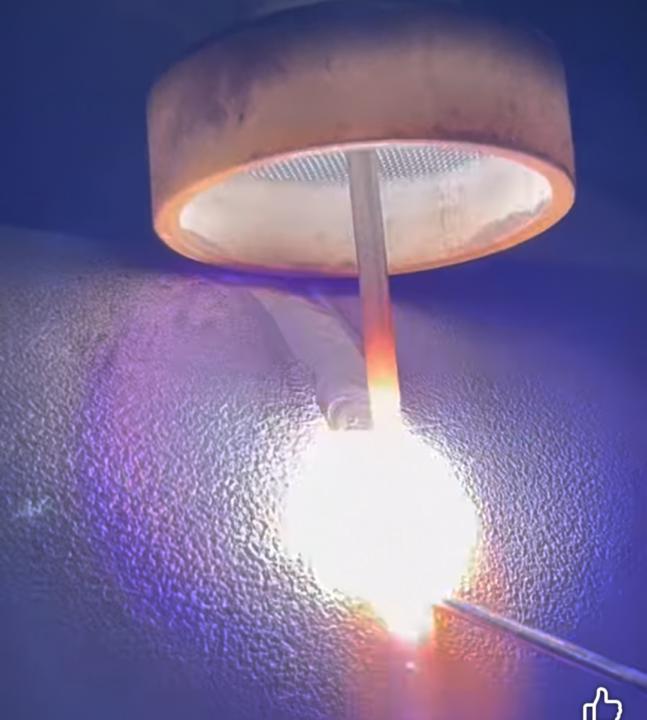

Heat Input

Great example of heat input. I always say if you touch a hot frying pan quickly you won’t get burned but if you lay your hand on it you will. Lower amps doesn’t mean less heat. I always try to move as fast as I possibly can until I reach the point where the puddles start being “V” shaped instead of “O” then I back off the speed a little. Watch your heat affected zone or “HAZ” on stainless it should be no more than very light gold! https://www.facebook.com/share/v/16zdxbp8Qk/?mibextid=wwXIfr

6

0

1-7 of 7

powered by

skool.com/motofab-performance-7936

1. Real time advice to level up your Fab skills

2. Community of other fabricators

3. And it’s Free!

Suggested communities

Powered by