Write something

Small Engine Carburetor Cleaning Tips.

Cleaning a small engine carburetor works best when you focus on passages, not just parts. Most carburetor problems aren’t caused by the carb being “dirty” on the outside. They’re caused by varnish and residue inside tiny fuel passages that restrict flow. Spraying the carb from the outside or just pulling the bowl off often isn’t enough. The most effective way to clean a carburetor starts with removing it from the engine. That allows proper access and prevents debris from being pushed deeper into the system. Once removed, the bowl, float, and jets should be taken out so fuel passages are exposed. Jets are especially important, even a small restriction can cause hard starting, surging, or poor throttle response. Carb cleaner should be used to flush passages, not just soak parts. Spraying through every opening and confirming cleaner exits somewhere else ensures passages are actually clear. Compressed air helps, but only after spraying cleaner through first. Never use wire or hard objects to poke jets, this can permanently change fuel flow. Gaskets and seals should be inspected before reassembly. Reusing damaged gaskets often leads to air leaks that create new problems after cleaning. Once reinstalled, fresh fuel makes a big difference, old fuel can undo good cleaning work quickly. A properly cleaned carburetor restores correct fuel delivery, improves starting, and brings back smooth throttle response. Taking the time to clean it thoroughly once is better than pulling it apart multiple times. When you’ve cleaned a carb in the past, what symptom were you trying to fix, hard starting, surging, or something else?

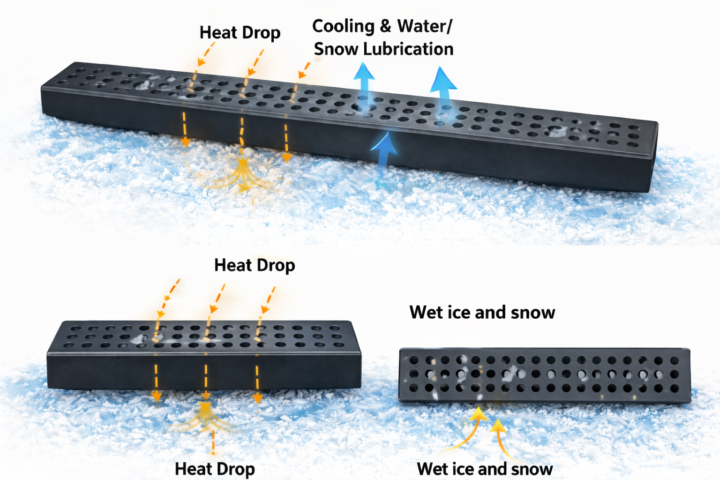

🔥 QUICK TECH TIP – HYFAX COOLING TRICK 🔥

Alright guys, here’s an old-school trick that still has some real mechanical logic behind it, especially for hard pack, ice riding, or radar/lake runs. 👉 You can drill small, shallow holes into your hyfax (sliders) to help with cooling and lubrication. The idea is NOT to drill all the way through. You just want shallow holes deep enough to hold snow and ice. As you ride, snow packs into those holes, melts slightly, and helps create a thin lubrication film between the rail and the slider. That helps reduce friction and heat buildup. This can help: ✔ Reduce slider overheating ✔ Reduce drag ✔ Improve durability in low snow conditions ✔ Help maintain speed on hard surfaces ⚠️ IMPORTANT: • Do NOT drill through the slider • Use small holes and space them evenly • Don’t remove too much material or you weaken the hyfax This trick works best in hard pack or icy conditions. Deep snow usually cools sliders naturally. Sometimes the old-school mechanical tricks still have solid engineering behind them. If you’ve ever tried this, comment below and share your results. Always cool seeing real-world testing from riders and techs. #TechTip #SnowmobileMaintenance #Hyfax #LefebvrePerformance

1

0

Cold Weather Equals a Stiff Belt

Bitter cold riding is some of the hardest riding a snowmobile will ever see, even if it feels like perfect sled weather. In extreme cold, metal contracts, rubber stiffens, and fluids move more slowly. That changes how nearly every system on the sled behaves, especially during the first few minutes of operation. Oil flows slower, bearings take longer to get proper lubrication, and belts don’t grip the same way until some heat is in the system. One thing many riders don’t realize is how much cold affects belt performance. A cold belt is stiff and less flexible, which can lead to slipping and heat buildup once load is applied. Giving the sled a few minutes to idle and then riding gently at first allows the belt and clutches to warm evenly, which helps prevent glazing and premature wear. Fuel behavior changes as well. Extremely cold air is dense, which can make engines feel sharper, but it can also highlight mixture issues that weren’t noticeable in warmer conditions. Hard starting, hesitation, or plug fouling can show up more easily on very cold days. Bitter cold riding isn’t something to avoid, it just requires a little patience. Letting the machine come up to temperature gradually and paying attention to how it feels in the first part of the ride goes a long way toward protecting belts, bearings, and internal components. Cold weather is great for snowmobiling, but it asks more from the machine.

2

0

Mower Blades, When was the last time you checked yours?

One of the most important and overlooked parts of a lawn mower isn’t the engine, it’s the blade. A sharp mower blade doesn’t just make the lawn look better, it directly affects engine load, fuel use, and long-term reliability. When a blade is dull, it tears grass instead of cutting it cleanly. That forces the engine to work harder, increases vibration, and can shorten belt and bearing life over time. Dull blades also stress the grass itself. Torn grass blades lose moisture faster and are more prone to disease, which leads to a lawn that looks brown or uneven even when everything else is set up correctly. From a mechanical standpoint, a sharp blade reduces resistance. That means smoother operation, more consistent RPM, and less strain on the engine, especially in thick or damp grass. It’s one of the simplest ways to improve mower performance without touching the engine at all. Blade condition should be checked regularly during the season, not just once a year. If the mower starts leaving ragged cuts, clumps grass more than usual, or sounds like it’s working harder than it should, the blade is often the reason. Good cutting starts at the blade. Everything else works better when that’s right. When was the last time you checked or sharpened yours?

Spark plugs are one of the simplest and most overlooked diagnostic.

Beyond firing the spark, a plug tells a story about what’s happening inside the engine. The colour and condition of the electrode and insulator can point to mixture, combustion quality, and operating conditions. A plug that’s light tan or gray typically indicates normal combustion. Dark, wet, or sooty plugs often point to rich operation, excessive idling, short run times, or cold-weather use where the engine never fully warms up. This is common on sleds and small engines that see lots of starts and stops. Plugs that look unusually white, blistered, or worn can indicate higher operating temperatures, lean conditions, or excessive load. That’s not something to ignore, especially on two-stroke engines where lubrication depends on proper mixture. Correct plug heat range matters. A plug that’s too cold may never burn off deposits and will foul easily. A plug that’s too hot can overheat and cause pre-ignition. Using the manufacturer’s recommended plug is usually the safest baseline unless other modifications are in place. The gap also matters more than people realize. A gap that’s too wide can cause a weak spark under load, while a gap that’s too tight can reduce combustion efficiency. Checking and setting the gap during routine maintenance helps keep starting and throttle response consistent. Spark plugs aren’t just parts you replace when something goes wrong. They’re one of the easiest ways to check engine health before problems show up. When was the last time you actually looked at the plug you pulled out?

1

0

1-22 of 22

powered by

skool.com/small-engine-repair-help-desk-4837

We teach small engine repair through clear explanations, hands-on troubleshooting, and real help in diagnosing and fixing common engine problems.

Suggested communities

Powered by