Write something

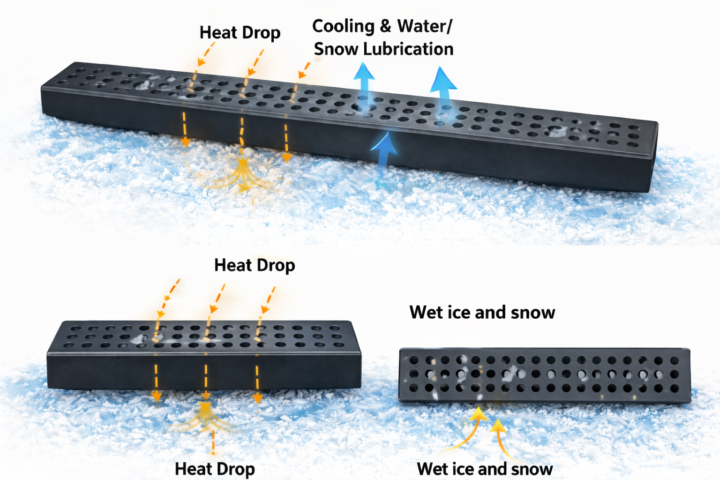

🔥 QUICK TECH TIP – HYFAX COOLING TRICK 🔥

Alright guys, here’s an old-school trick that still has some real mechanical logic behind it, especially for hard pack, ice riding, or radar/lake runs. 👉 You can drill small, shallow holes into your hyfax (sliders) to help with cooling and lubrication. The idea is NOT to drill all the way through. You just want shallow holes deep enough to hold snow and ice. As you ride, snow packs into those holes, melts slightly, and helps create a thin lubrication film between the rail and the slider. That helps reduce friction and heat buildup. This can help: ✔ Reduce slider overheating ✔ Reduce drag ✔ Improve durability in low snow conditions ✔ Help maintain speed on hard surfaces ⚠️ IMPORTANT: • Do NOT drill through the slider • Use small holes and space them evenly • Don’t remove too much material or you weaken the hyfax This trick works best in hard pack or icy conditions. Deep snow usually cools sliders naturally. Sometimes the old-school mechanical tricks still have solid engineering behind them. If you’ve ever tried this, comment below and share your results. Always cool seeing real-world testing from riders and techs. #TechTip #SnowmobileMaintenance #Hyfax #LefebvrePerformance

1

0

Cold Weather Equals a Stiff Belt

Bitter cold riding is some of the hardest riding a snowmobile will ever see, even if it feels like perfect sled weather. In extreme cold, metal contracts, rubber stiffens, and fluids move more slowly. That changes how nearly every system on the sled behaves, especially during the first few minutes of operation. Oil flows slower, bearings take longer to get proper lubrication, and belts don’t grip the same way until some heat is in the system. One thing many riders don’t realize is how much cold affects belt performance. A cold belt is stiff and less flexible, which can lead to slipping and heat buildup once load is applied. Giving the sled a few minutes to idle and then riding gently at first allows the belt and clutches to warm evenly, which helps prevent glazing and premature wear. Fuel behavior changes as well. Extremely cold air is dense, which can make engines feel sharper, but it can also highlight mixture issues that weren’t noticeable in warmer conditions. Hard starting, hesitation, or plug fouling can show up more easily on very cold days. Bitter cold riding isn’t something to avoid, it just requires a little patience. Letting the machine come up to temperature gradually and paying attention to how it feels in the first part of the ride goes a long way toward protecting belts, bearings, and internal components. Cold weather is great for snowmobiling, but it asks more from the machine.

2

0

Mild Conditions and Heat Exchangers.

Mild riding conditions can be harder on your snowmobile than deep cold, especially when it comes to heat exchangers. Heat exchangers rely on snow contact to shed engine heat. In mild conditions, there’s often less loose snow being thrown up onto the exchangers, even though ambient temperatures feel comfortable to ride in. That combination can lead to higher operating temperatures without obvious warning signs at first. Hard-packed trails, icy surfaces, or low-snow conditions reduce cooling efficiency. The sled may feel fine to ride, but coolant temperatures can creep up, especially during steady cruising or slower trail sections where airflow and snow spray are limited. This doesn’t mean you shouldn’t ride in mild conditions. It means being aware of how cooling works and adjusting habits when snow coverage is marginal. Backing off the throttle occasionally, varying speed, avoiding long slow sections, and keeping exchangers clean all help manage heat. It’s also a good reminder to keep an eye on temperature readings and warning lights. Heat-related stress builds quietly, and catching it early helps protect engines, hoses, and seals over the long term. Mild weather riding can be great, it just asks a little more attention to cooling. Have you noticed higher temps or warning lights when snow coverage is thin?

1

0

Have You Checked Your Track?

Loose tracks don’t always start loose, vibration can be the reason they end up that way. Snowmobiles operate in conditions that create constant vibration, especially on hard-packed trails, icy sections, or when running aggressive tracks and studs. Over time, that vibration can cause adjusters and hardware to settle or move slightly, even if the track was set correctly at the start of the season. A track that begins to loosen may not be obvious right away. Early signs often include increased vibration, wandering under throttle, or a change in how the sled feels when accelerating or decelerating. Left unchecked, a loose track can wear components faster, affect handling, and increase stress on the drivetrain. Checking track tension periodically is part of good maintenance, not a sign something was done wrong. Small adjustments made early help prevent bigger issues later, especially as conditions change and components heat cycle through the season. Track tension isn’t about setting it once and forgetting it. It’s about monitoring how the sled behaves and making minor corrections when needed. Have you noticed your track loosening as the season goes on, or do you check tension regularly?

Snowmobile Performance, what’s what

When people talk about snowmobile performance upgrades, a few changes come up over and over because they actually make a difference. One of the most common performance enhancements right now is clutching changes. Proper clutch setup helps the engine stay in its power range, improves throttle response, and makes the sled pull more consistently in different conditions. This is often felt immediately and doesn’t rely on chasing peak horsepower. Another popular upgrade is exhaust changes. A lighter, better-flowing exhaust can improve throttle response and reduce overall weight. The benefit depends heavily on proper tuning, otherwise gains can be minimal or reliability can suffer. Suspension tuning and upgrades are also high on the list. While they don’t add engine power, they help the sled use its power more effectively by improving traction, control, and rider confidence. For many riders, this feels like a bigger performance improvement than engine work. Changes to tracks and skis are common as well. Track choice affects acceleration, braking, and flotation, while skis influence steering and stability. These upgrades often improve how the sled feels without touching the engine at all. Finally, engine tuning plays a role, whether that’s jetting, fuel adjustments, or electronic tuning. Matching fuel delivery and timing to the sled’s setup and riding conditions can make a noticeable difference in how smooth and responsive the engine feels. There’s no single upgrade that works best for everyone. The most effective performance changes depend on how and where the sled is used, trail riding, deep snow, utility work, or a mix of everything. What performance change has made the biggest difference on your sled, or what are you considering next?

1

0

1-6 of 6

powered by

skool.com/small-engine-repair-help-desk-4837

We teach small engine repair through clear explanations, hands-on troubleshooting, and real help in diagnosing and fixing common engine problems.

Suggested communities

Powered by