Pinned

🙌 AIS is the #1 Tech Skool Community... but we need your help

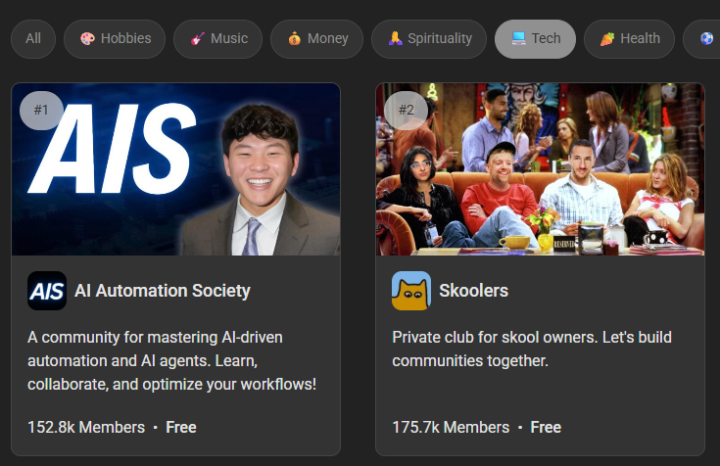

Hey AIS fam, Good news and bad news. The good news, our community just hit #1 in the Tech category and #2 overall on Skool out of more than 175,000 communities! That’s incredible and a huge credit to all of you. The bad news is that with the growth, we’re seeing more spam, self-promotion, and discussions that aren't focused on AI or automation. Please help us keep this space clean and valuable by reporting any spam or self-promotion you see. Our admin team will take care of it quickly. This community is growing because of you, your engagement, questions, and support for one another. Let’s keep building a safe, focused space to learn and grow together. Cheers, Nate

Pinned

🚀New Video: I Tested OpenAI's AgentKit Against n8n: What You Need to Know

In this video, I compare OpenAI’s new AgentKit to n8n to see how they stack up against each other. We’ll go over what each platform is, how they work, and what makes them unique. I’ll walk you through how to access and set up AgentKit, explore its features, and then put both tools head-to-head across different categories. I also score each one so you can clearly see their strengths and weaknesses. Most importantly, I’ll help you figure out when you should use one over the other, because the truth is, they’re built for different purposes and appeal to different types of builders. Whether you’re just getting started or already deep into automation, this video is a full, easy-to-follow guide to help you choose the right tool for your next project.

Pinned

🚀New Video: How I'd Make Money with AI in 2026 (if I had to Start Over)

In this video I'm going to be teaching you how I'd make money with AI in 2026, if I had to start over from scratch. This will be the most actionable video you've ever seen about making money with AI. I'll breakdown everything, and fitting it all into this easy to learn 24 minute guide. Hope you enjoy!

Eliminated Their 6-Person Data Entry Team with One Weekend Build

Manufacturing client: "We have 6 people doing data entry from supplier invoices. Can automation help?" THE MANUAL BOTTLENECK - 6 full-time data entry clerks - 2,000+ supplier invoices monthly - 15 different ERP systems (acquisitions over 20 years) - Processing time: 8 minutes per invoice - Error rate: 9% - Annual cost: $234,000 THE WEEKEND AUTOMATION BUILD Used my manufacturing template, customized for their complexity: MULTI-ERP INTEGRATION WORKFLOW (18 nodes) Input processing (Nodes 1-3): - Email attachment monitoring (15 supplier email accounts) - FTP server polling (legacy suppliers) - Manual upload portal for exceptions Invoice intelligence (Nodes 4-8): - Vendor detection and routing - Purchase order matching - Line item extraction and validation - Tax calculation verification - Approval workflow routing ERP integration layer (Nodes 9-15): - System routing based on division/vendor - SAP integration (3 instances) - Oracle integration (2 instances) - QuickBooks Enterprise (4 instances) - Legacy systems (6 custom APIs) - Data format transformation per system Quality control (Nodes 16-18): - Cross-system validation - Exception handling and alerts - Audit trail generation BUILD TIMELINE Friday evening: Started development Saturday: Core workflow and testing Sunday: ERP integrations and validation Sunday evening: Production deployment Total build time: 16 hours over weekend THE IMMEDIATE IMPACT Week 1 results: - Processing time: 8 minutes → 45 seconds per invoice - Accuracy: 91% → 98.4% - Throughput: 2,000 invoices/month → 4,500 capacity - Human intervention: <3% of invoices Month 1 transformation: - Eliminated 6 data entry positions - Redirected staff to supplier relationship management - Reduced invoice processing errors by 89% - Improved cash flow through faster processing ANNUAL SAVINGS CALCULATION - Staff costs eliminated: $234,000 - Error reduction value: $48,000 - Faster processing benefits: $67,000 - Total annual impact: $349,000

Starting my n8n journey!!1

Hey all AI Enthusiast out there, I'm starting my AI journey by learning n8n. I'm watching the mastercalss on n8n and I'm curioused to learn more and I can see endless possibilities how it can help me grow my business. I'm happy to be here and see everyone share their works here. I'll start sharing my workflow here soon

1-30 of 7,589

skool.com/ai-automation-society

A community for mastering AI-driven automation and AI agents. Learn, collaborate, and optimize your workflows!

Powered by