Activity

Mon

Wed

Fri

Sun

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

What is this?

Less

More

Memberships

Drone Coach Collective

204 members • Free

Military Maintainers

427 members • Free

Aviator Intelligence

1.8k members • Free

ValueKnow: Aerospace Community

44 members • Free

1 contribution to ValueKnow: Aerospace Community

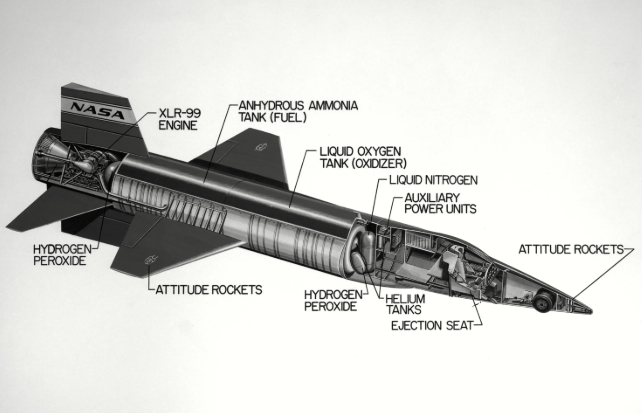

X-15 and Space Shuttle Maintenance

As always, please feel free to post documents, insights, links, ideas, questions and more (even memes!). I would love to see this community move to an open aerospace forum where everyone feels welcome to participate. By doing so, you will raise your community level and will be able to access additional aerospace content. Looking back from 2026, the X-15 remains a pivotal chapter in aerospace history as a rocket-engine-powered research vehicle that pushed the boundaries of the 20th century, regularly conducting flights to altitudes exceeding 250,000 feet and speeds greater than Mach 5. The historical data records the aircraft as having an overall length of 50 feet and a wingspan of 22 feet 4 inches, with a launch weight of 34,000 pounds that dropped to 15,500 pounds by landing. Retrospective analysis of its maintenance logs reveals that while individual repair items between flights were often small, their sheer volume created a significant cumulative maintenance burden that could severely impact flight schedules. Regarding the Space Shuttle program that followed, documents from 1970 reveal that engineers correctly anticipated that while the Shuttle would utilize equipment and materials newer than those of the X-15, its systems would be vastly more complex and operate in a much more severe environment. These early assessments warned that the increased system complexity would magnify the number of repairs, making the required turnaround times difficult or impossible to achieve without a strict focus on problem prevention and accessibility. The industry understood that minimizing maintenance items was essential for the Shuttle's success, based directly on the labor-intensive lessons learned from the X-15. A review of the X-15's archival maintenance data highlights that propellant pneumatic system leaks and structural repairs were the primary obstacles to quick turnaround. Statistical breakdowns from the era show that out of 41 specific leaks analyzed, a significant number occurred in the hydrogen peroxide (H2O2) and helium systems, often caused by O-rings and seals drying out during periods of inactivity. These historical records indicate that even when the leaks were simple, they frequently required extensive structural work just to access the plumbing, complicating the pre-flight and post-flight servicing processes.

1 like • 18d

The 2026 takeaway is that reusable systems succeed or fail on maintenance access, fault isolation, and touch-labor per flight, not on peak performance. The X-15 lesson still holds "small” leaks and minor repairs become messes up the entire schedule when access requires structural removal, and intermittent “ghost” faults demand repeatable ground replication with better onboard data capture. That’s the same reality facing modern reuse efforts and airline dispatch reliability. If you want rapid turnaround, you have to design for accessibility, built-in test, and fast inspection, or the ops concept collapses from the cumulative maintenance hours.

1-1 of 1

@mathew-lewallen-7595

Aviation Operations 🔹 Air Traffic Management 🔹 Airspace Integration 🔹 FAA/ICAO Policy 🔹 Safety & Emergency Response 🔹 Global Airspace Operations

Active 13d ago

Joined Jan 20, 2026

Charleston, SC