Activity

Mon

Wed

Fri

Sun

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

What is this?

Less

More

Owned by Lluís

✈️ Interested in Aerospace Engineering? 70k+ students worldwide have taken our courses. Join our Community NOW and get 2 FREE Aerospace Courses.

Memberships

8 contributions to ValueKnow: Aerospace Community

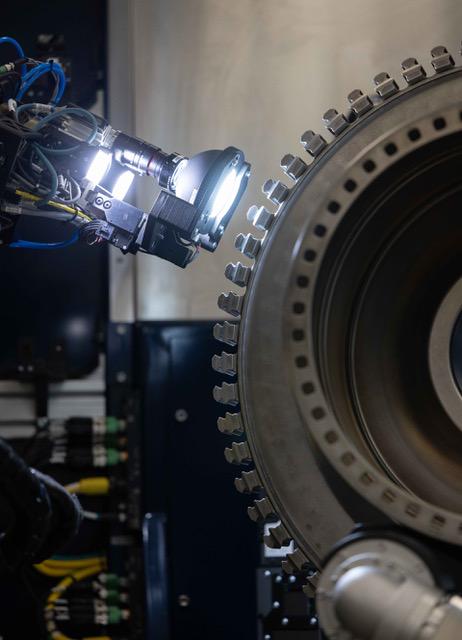

White Light Inspection Robots

As always, please feel free to post documents, insights, links, ideas, questions and more (even memes!). I would love to see this community move to an open aerospace forum where everyone feels welcome to participate. The implementation of AI-guided white light robot inspection represents a significant shift toward digitizing maintenance, repair, and overhaul (MRO) workflows. This system is engineered to minimize measurement variability while maximizing inspection velocity. The primary technical objective is the creation of a centralized, life-cycle data repository that digitally captures all characteristics of in-service components, establishing a foundational dataset for consistent technical disposition throughout a part's service life. This automation stems from the rigorous requirements of inspecting Life-Limited Parts (LLP), such as high-pressure turbine (HPT) disks located at the engine core. These components demand precise identification of surface anomalies, including specific failure modes like fretting, corrosion, dents, and scratches, which dictate engineering acceptance or rejection. Current manual methodologies depend on visual inspection using mirrors and flashlights, a process plagued by ergonomic challenges and significant operator fatigue over 8 to 12-hour shifts. Consequently, the interpretation of surface features can suffer from high variability between individual inspectors, leading to inconsistent disposition decisions. To mitigate these human factors, the white light inspection architecture deploys two articulated industrial robots within a universal workstation. These units are equipped with advanced white light optical scanners designed to traverse the complex geometries of high-precision components, such as GE-90 turbine disks. The system utilizes AI-driven path planning to choreograph the robots' movements in close proximity to the part surface, enabling the automated capture and analysis of topographic data with repeatable accuracy and speed.

1

0

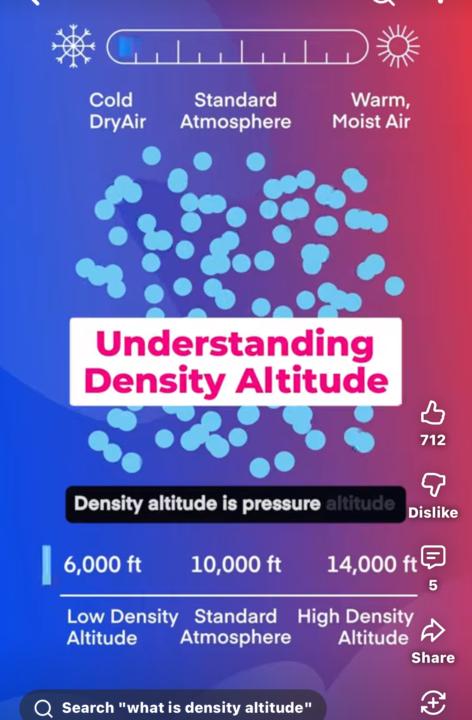

Understanding Density altitude

What is density altitude ? . I’m Having trouble understanding it

1 like • 10d

Hi Emmanuel, density altitude is pressure altitude corrected for non-standard temperature. While pressure altitude describes the weight of the air above you, density altitude tells your airplane how many air molecules are actually available for its wings and engine to use. On a hot day, air molecules move at high speeds, bouncing off each other violently and pushing apart; this makes the air "thin" and less dense, forcing the aircraft to perform as if it were thousands of feet higher than it actually is. Conversely, on a cold day, air molecules slow down and settle closer together. This creates a low density altitude where the air is "thick" and packed with energy; the engine breathes in more oxygen and the wings find more "grip" in the crowded air, leading to a significant boost in performance. Essentially, density altitude is the performance altitude: it’s the environment the airplane "feels," regardless of what the altimeter says.

1 like • 8d

@Emmanuel Mlj Flying at 5,000 feet under high density altitude conditions forces your aircraft to perform as if it were at a much higher altitude. Because the low air density reduces engine power, propeller efficiency, and wing lift simultaneously, you will experience a takeoff with an extended ground roll and a reduced rate of climb. While your indicated airspeed remains unchanged, your true airspeed and ground speed must be higher to generate the necessary lift. On a very cold day, the low density altitude creates "thicker" air that shortens takeoff rolls, boosting climb performance, and making the controls feel more responsive with more grip.

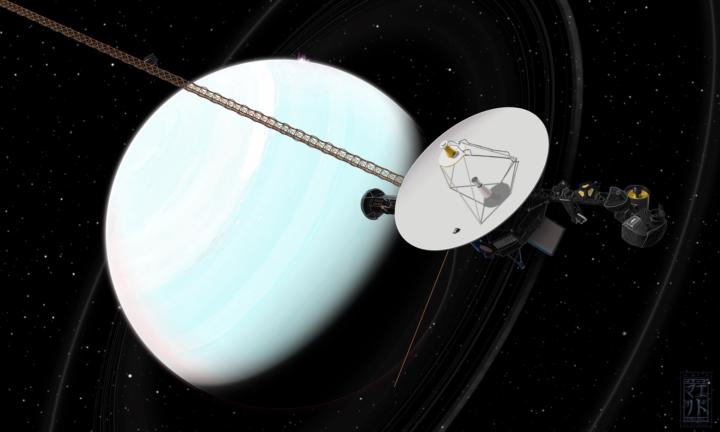

Voyager Missions Explained

As always, please feel free to post documents, insights, links, ideas, questions and more (even memes!). I would love to see this community move to an open aerospace forum where everyone feels welcome to participate. For those of you who know me well, you know I am a deep space engineering fan. Let's discuss the Voyeger Missions, which were a massive success in acquiring most of the images of the planets that you may be familiar with. The Voyager missions were born from the requirement to exploit a rare planetary alignment that happens once every 175 years, allowing for a "Grand Tour" via successive gravity assists. The primary mission objective was to characterize the magnetospheres, atmospheres, and satellite systems of the Jovian and Saturnian systems. By utilizing the orbital momentum of the planets, NASA could reduce the required propellant mass, allowing the probes to achieve the escape velocity necessary to exit the solar system entirely. This celestial mechanics opportunity necessitated the development of a spacecraft capable of high-level autonomous fault protection, as the round-trip light time for communication would eventually reach several hours. During the initial deployment phase in 1977, the probes utilized the Titan IIIE/Centaur launch vehicle to achieve an Earth-escape trajectory. Voyager 2 was launched on a slower, more flexible path to ensure it could reach Uranus and Neptune if the primary mission succeeded, while Voyager 1 was placed on a high-velocity "interceptor" path to Jupiter and Saturn. The navigation relied on precise Deep Space Network (DSN) tracking to execute Trajectory Correction Maneuvers (TCMs). As the probes encountered Jupiter, they utilized a "gravity-assist" maneuver, where the planet’s orbital velocity was transferred to the spacecraft, boosting their speed relative to the Sun while bending their flight paths toward their next targets. Technologically, the Voyager probes are powered by three Multi-Hundred Watt Radioisotope Thermoelectric Generators (MHW-RTGs), which utilize the 24,110-year half-life of 239Pu (initially 238Pu for heat) to generate electrical power through the Seebeck effect. The telecommunications subsystem features a 3.7-meter parabolic high-gain antenna (HGA) communicating via S-band and X-band frequencies. For scientific data collection, the probes carry an Integrated Science Instrument Subsystem (ISIS), which includes a Plasma Science (PLS) instrument, a Cosmic Ray Subsystem (CRS), and a triaxial fluxgate magnetometer mounted on a 13-meter deployable boom to isolate the sensors from the spacecraft’s own magnetic interference.

1

0

A Christmas Aerospace Story: The Shepherd

Here is the story of the Shepherd, for those of you who may not have heard of it: The story of "The Shepherd" is a cornerstone of aviation folklore, written by Frederick Forsyth. Set on Christmas Eve in 1957, it captures the transition between the aging piston-engine era and the new age of jet flight. The narrative follows a young, cocky Royal Air Force pilot flying a De Havilland Vampire from West Germany back to England for his holiday leave. What begins as a routine sixty-minute flight across the North Sea quickly turns into a desperate struggle for survival when his aircraft suffers a total electrical failure, leaving him without a radio, navigation instruments, or a way to see through the thick fog closing in on the English coast. As the pilot begins flying "blind" in a triangle pattern, an international distress signal, he resigns himself to a watery grave in the freezing sea. Just as his fuel reaches its limit, a vintage World War II De Havilland Mosquito bomber emerges from the fog. The pilot of the Mosquito, acting as a "Shepherd," uses hand signals to guide the modern jet through the soup of clouds. With pinpoint accuracy, the mysterious escort leads the Vampire to a safe landing at a remote, derelict airfield. The engine of the Vampire flutters and dies the moment the wheels touch the tarmac, saved by seconds of fuel and the precision of the stranger. The emotional core of the story arrives when the pilot seeks out his savior, only to find the airfield nearly abandoned. Upon speaking with a local caretaker and seeing an old photograph on the wall, he realizes that the pilot who guided him home was John "Joe" Kavanagh, a legendary "shepherd" of the skies who specialized in bringing crippled bombers home during the war. The chilling realization is that Kavanagh and his Mosquito had been lost at sea exactly fourteen years earlier, on Christmas Eve, 1943. The story ends with the implication that even in the cold isolation of the cockpit, no pilot is ever truly flying alone.

Boeing 787: a More Electric Aircraft

As always, please feel free to post documents, insights, links, ideas, questions and more (even memes!). I would love to see this community move to an open aerospace forum where everyone feels welcome to participate. The development of the Boeing 787 Dreamliner represented a radical departure from traditional aerospace engineering, moving toward a "More Electric" architecture that replaced heavy pneumatic systems with electrical actuators. To power this leap in technology, Boeing selected Lithium-Ion (Li-ion) batteries due to their superior energy density and weight savings compared to traditional nickel-cadmium alternatives. However, the path to innovation was rocky; even before the 2013 grounding, the flight test program faced a setback in 2010 when a test aircraft (ZA002) suffered an onboard electrical fire in its power distribution bay. This early incident, attributed to foreign object debris (FOD) causing a short circuit, served as a precursor to the systemic electrical challenges that would later plague the fleet's entry into service. The primary "fires" associated with the 787 occurred in January 2013, when two separate aircraft operated by Japan Airlines (JAL) and All Nippon Airways (ANA) suffered catastrophic battery failures. The JAL incident involved an auxiliary power unit (APU) battery catching fire while the plane was parked in Boston, while the ANA flight was forced to make an emergency landing in Japan after pilots detected smoke in the cockpit. These back-to-back events led to a historic decision by the FAA to ground the entire global 787 fleet—the first time an entire aircraft type had been pulled from service since the DC-10 in 1979. The grounding lasted four months as investigators and engineers scrambled to identify the root cause of the smoke and flames emanating from the aircraft's electronics bays. Technically, the failures were identified as a phenomenon known as thermal runaway. Investigators discovered that an internal short circuit in a single cell, likely caused by manufacturing defects, microscopic "dendrites," or contamination, triggered a cascading chain reaction. As the first cell overheated and vented flammable electrolyte, the heat transferred to adjacent cells, causing the entire 8-cell battery pack to fail in a violent release of toxic smoke and high-temperature fire. The NTSB later criticized Boeing's original safety assessments, which had predicted such a failure would occur only once in every 10 million flight hours; in reality, two failures occurred in less than 52,000 hours, revealing a significant "blind spot" in the industry’s understanding of large-scale lithium-ion behavior in aviation.

2

0

1-8 of 8

@lluis-foreman-8720

Lluís Foreman, Aerospace Engineer MSc

Active 7m ago

Joined Nov 29, 2025