Activity

Mon

Wed

Fri

Sun

Oct

Nov

Dec

Jan

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

What is this?

Less

More

Memberships

MotoFab Welding SKOOL

82 members • Free

15 contributions to MotoFab Welding SKOOL

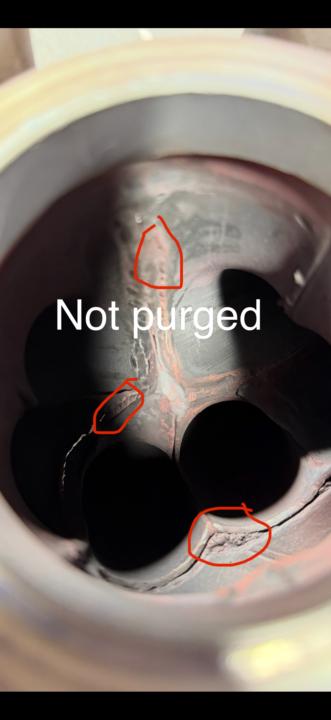

R33 GTR Manifold Failure

This is a manifold for an R33 GTR sent to me by a customer for me to build him a new manifold, videos on that coming soon. I am going to break down the weld defects and why they cause failure. 1. Undercut - Undercut is the gouge at the edges of the weld, undercut happens from the puddle or the part getting too hot and pulling too much material from the base metal into the puddle. This can be avoided by keeping the part and puddle from overheating and by adding enough filler rod. Undercut causes weakness by thinning out the base material and creating a point that is vulnerable to stress. 2.No purge - Not purging stainless steel causes a few issues, the first is lack of fusion, the puddle when it penetrates through the material is not able to fully melt the part together because it is exposed to oxygen on the other side and oxidizes before it can fuse. The second problem is that the rough chromium carbide precipitation also known as “sugar” can break off and enter the turbocharger causing damage. It also is not ideal for flow to have a rough lumpy surface. 3. Lack of penetration, in the 4th photo you can see the weld looks ok and has no undercut. When a weld cracks at the edge it is due to undercut or lack of fusion to the base metal. In the case the weld cracked in the center because it was run cold without enough penetration meaning that the overall thickness of the weld material was much thinner and weaker than the base metal.

Viper Swapped dodge charger

Viper header #1 is mocked up, this weekend I will get the other one on and then I just need an oil filter relocation kit and I can get this engine in position for building motor and transmission mounts. I will be making a video on that process so stay tuned on the youtube channel!

New project!

Not necessarily directly welding related, but I’ve been working on making my own kit for schd 10 header mock up with my 3D printer. 15° tick marks to help with clocking, I’ve got long and short radius 90° bends, and 45° elbows that just bolt together(need some shorter bolts). Excited to get some more printed and getting runners mocked up!

Asking questions is the best way to learn!

Hey guys just a reminder that this group is here for YOU! I created this group to help you guys get better at welding/fab and I want to hear from you! If you have a problem post it, post pictures of your welds that you want tips on improving, or just share your work to show the group what you’re doing! I’ll go first, this is some of the work I did on the 1000+ hp Impreza drag car: Steel to steel strut tower plates welded with 309 stainless rod and a .083 thick chromoly rear strut bar!

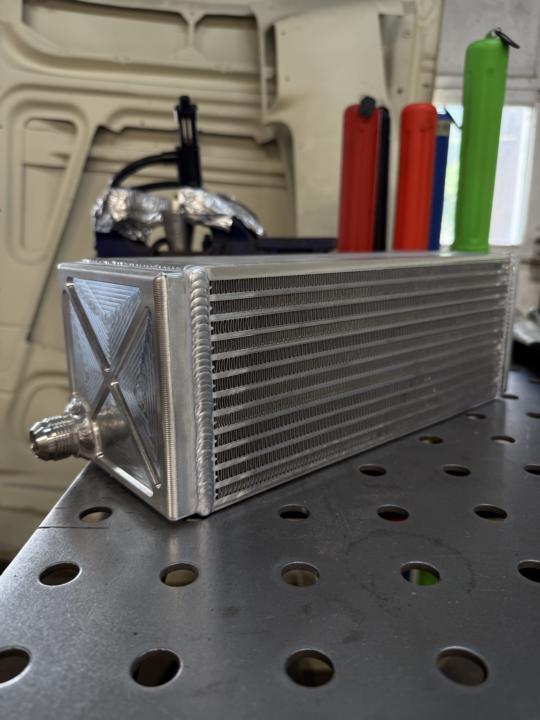

Lamborghini Gallardo Air to Water Intercoolers.

Sneak peak for you guys about what my next video is on!

1-10 of 15

@ethan-white-4151

Hey there! I’m Ethan, I’ve got a passion for anything automotive related, especially fabrication!

Active 2d ago

Joined Aug 27, 2025

Eagle Mountain, Utah