Activity

Mon

Wed

Fri

Sun

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

Feb

What is this?

Less

More

Memberships

SOLIDWORKS Accelerator

2.2k members • Free

21 contributions to SOLIDWORKS Accelerator

Will you help me by being its early followers?

Hey everyone, I’m excited to announce that SolidWorks Course Pro now has its own LinkedIn page! 🎉 Will you help me by being its early followers? This page will be your go-to hub for: ✅ Industry updates and tips on mastering SolidWorks ✅ Success stories and highlights from our incredible community ✅ Behind-the-scenes insights and exclusive announcements If SolidWorks has made a difference in your career (or you’re just starting your journey), let’s continue growing together. Your support means everything, and by following the page, you’ll stay connected with everything we’re working on to make your experience even better. 👉 Follow us here: https://www.linkedin.com/company/solidworks-course-pro Thank you for being part of this amazing community. Let’s make SolidWorks Course Pro even bigger and better—together! Best, Aryan

Wanted to show off my recent...

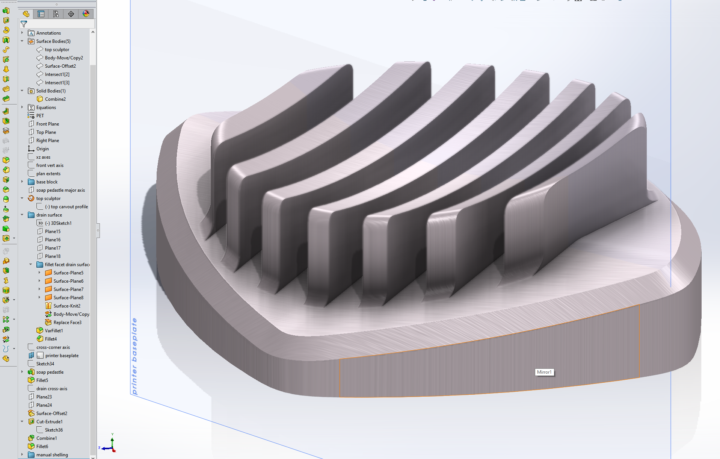

Behold my mighty soap dish! Are you not awed at its magnificence?!? Seriously though it has been a lot of effort and learning surfaces and I even managed to corrupt the file at one point trying to automatically shell the bottom face after doing the fins on the top face. Let me know what you think. (I know, I know I should be moving through the coursework, but this is fun, and girlfriend's soap is always melting) i cleaned up the feature tree because this part is more or less done, but there is still a bit of junk in there. I had a terrible time getting the variable fillet to be stable on the top face when i first made it (likely part of what led to the SW-crashing shell command failure) but later on I did the same type of operation while manually shelling and it went pretty much perfectly.... i guess practice makes perfect (or was it Fillet Options > Overflow Type > Keep surface ... hmmm) The plan is to split the model on the plane shown and print two halves in vase mode with a fat nozzle, then solvent-weld them together. Though looking at it now it seems like I will need to remodel the fin profiles because the fat nozzle will make the fins at the edges not turn out right, and the fillets on the bottom of the fins will be more or less invisible. Next I will learn some in-context assembly work because I want to have a separate part that snaps in the bottom to register the part for the glueing as well as hold some non-slip feet.

2 likes • Nov '24

@Jesse Davis I was thinking the same thing as far as the egg slicer goes. Maybe you could make two models and the second one would be an egg slicer (just in solidworks for practice) since I'm not sure how you would actually make the slicing top portion in reality. Overall, great job.

1 like • Nov '24

@Jesse Davis While I understand the engineering function of the top cutting piece, my focus was on how you would actually make that top cutter. I picture the top being a simple frame that has a way to securely pin segments of piano wire at regular intervals to form the cutters. I think it is definitely capable of being done.

Gear Box is done, but...

I've finished the gearbox, but the masses don't line up with the Mini quiz. I couldn't open the SKF files in SolidWorks so I went to SKF and downloaded the one who's number matched the data in the supplied file name. I assigned stainless steel (ferritic) at 7800kg/m^3 as instructed for all components including the bearings, but the masses don't match the quiz.

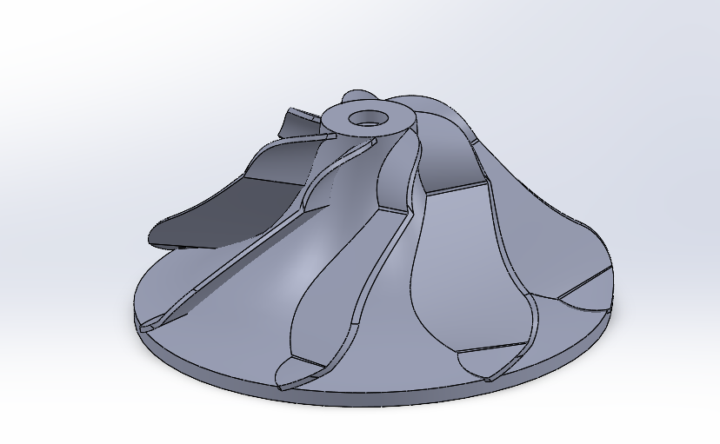

First Impeller

Back from vacation and this is the continuation of the "harder gearbox set". I tried to get the internal line to be more smooth but somehow it kept giving me a strangely complex fin arrangement, so I just went with it. I put the insets in the impeller for some bearings and a shaft. OK community, How does it look? I do like the star shape that just happened to appear.

Should we have a live session?

please answer YES, ONLY IF YOU WILL attend the session for SURE! Otherwise, please vote No, or Don't Know Should I go live to answer your technical questions in October? (If I get more than 100 yes votes, I'll put another poll for finding the right time) Hint: I will try to hold the session during a weekend (Sat or Sun)

Poll

61 members have voted

1-10 of 21

@daniel-laughman-5441

I work in the Power Plant design industry and need to have a few more skills.

Active 265d ago

Joined Jul 27, 2024

Powered by