Write something

Pinned

Resources linked here

K-Series tuning and next step guide https://docs.google.com/document/d/1CvmgTBotyHOnw6V7_6m9NKWiZlmypZpgbnjvJ2RLOk8/edit?usp=drivesdk

0

0

Pinned

START HERE: Welcome to Outlaw Performance Academy

START HERE: Welcome to Outlaw Performance Academy Tuning K-series on Hondata K-Pro. Every log, every mistake, every fix shared with you. No edits. No posturing. Just real progress.” What happens here • Live Tune Lab (Weekly Coming Soon): screen-share, troubleshoot, apply changes. • Datalog Clinic( Coming Soon ): post logs → get precise fueling/ignition/cam angle calls. • Roadmap + checklists: step-by-step path from base map to WOT. • Mindset: Goals, identity, execution. First 15 minutes (do this now) 1. Comment “I’m in.” 2. Introduce your build ([BUILD]) with: chassis • engine (K20/K24) • ECU (K-Pro) • fuel (93/E85) • injectors (brand/size/data) • header/intake/exhaust • compression (if known) • KManager version • base map (name/date) • goals. 3. Turn on notifications for Announcements, Live Tune Lab, Datalog Clinic. 4. Grab the Roadmap ( Coming Soon ) in Classroom: base map → idle/part-throttle → VTEC/WOT → cam angle → fueling → ignition. 5. Record a baseline log (5–8 min): idle → light cruise → brief VTEC touch, then upload to Datalog Clinic. Log channels: RPM, TPS, MAP, AFR/λ, STFT, LTFT, Ign Advance, Knock/Retard, IAT, ECT, Intake Cam Angle, VTEC status. Fast lane for help Post a [HELP Project] thread with: • Build sheet (from above) • Exact issue (e.g., “lean tip-in @ 2,500–3,000 rpm, light throttle”) • What you changed (tables/cells, % change) • Attachments: latest KManager calibration + datalog and a screenshot of target vs measured AFR • When fixed, edit title to [SOLVED] Safety (read before WOT) • If compression/leakdown fails, stop and post. • If trims swing > ±10% at cruise, stop and post. • If knock appears or AFR is unknown, stop and post. • Track or dyno only. House rules Data over opinions • Help the next guy • One problem per post • Keep it tight and actionable. The creed Forge the Man. Forge the Machine. Drop your build, Introduce yourself and upload your data logs.

0

0

What knock margin means

What knock margin means (simple) Knock margin = how much safety buffer you have before knocking starts. - More margin = you can run more timing / more load before knock. - Less margin = knock happens sooner, so you have to back off. Why hotter IAT/ECT reduces it Hotter charge/chamber = the mixture is closer to auto-igniting, so you have less room to push timing or load before it knocks. Quick analogy: If the knock limit is a “redline temperature,” hotter IAT/ECT starts you closer to redline → less margin.

0

0

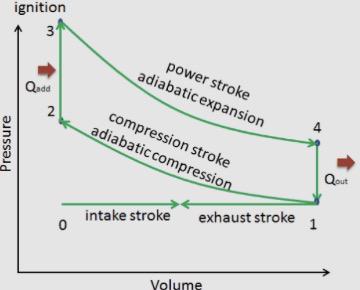

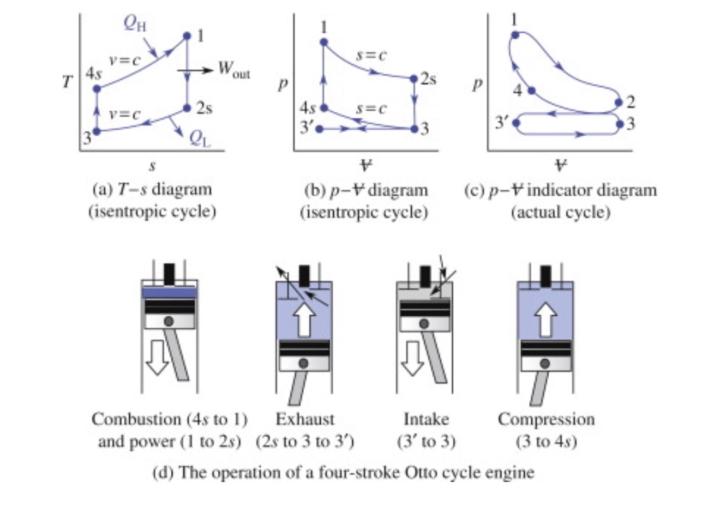

Why knowing the OTTO cycle is important to fully understand.

Why knowing the OTTO cycle is important to fully understand. The Otto cycle is the physics contract your tune should follow. If you do internalize it, every change you make has a predictable direction, and you can debug problems fast. What this means the idealized Otto cycle model (the physics contract we’re exploring), there’s a very specific assumption made about when and how that heat addition happens relative to the piston’s movement. This is what makes the model so useful for predicting outcomes in tuning In any engine or thermodynamic process. When you add heat to a gas, that heat can do two main things it can increase the temperature (and thus internal energy) of the gas, or it can cause the gas to expand and do work on the surroundings (like pushing the piston down). Core rule for the OTTO cycle When heat is added with no room for the gas to expand (piston at TDC, volume fixed), nearly all that heat energy goes into raising the temperature and pressure sharply inside the cylinder. There’s almost no immediate mechanical work done during the combustion phase itself. By spiking the pressure so dramatically right at TDC (through heat addition at fixed volume), the model creates an extremely high force on the piston the moment it begins its downward stroke. That high initial pressure means the gas can do a lot of work as it expands and pushes the piston over the full stroke length, converting more of the added heat into mechanical work rather than wasting it as exhaust heat. This is what makes the idealized Otto cycle so efficient compared to other cycles: the work output during the power stroke is maximized because the pressure starts so high and then drops gradually (ideally isentropically) as volume increases.

0

0

OTTO Cycle explain series

OTTO CYCLE What is the Otto Cycle? Does it explain the ideal spark ignition cycle on a four stroke engine. Keep following this series to find out If you don’t know what the four strokes are here they are Intake - Air fuel comes in Compression - piston squeezes it Power - spark plug ignites mixture forcing piston down Exhaust- Piston pushes it out. Engine is nothing more than an Air Pump with combustion energy from the explosion on the power stroke The goal in the Otto Cycle is to control when and how fast the pressure rise happens during the power stroke.

0

0

1-8 of 8

powered by

skool.com/outlaw-forged-academy-7849

The underground academy for gearheads who want to build cars, race to dominate, and live life wide open.

Suggested communities

Powered by