Jan 7 • Beef

Mastering Beef rib

If you’ve ever tucked into a beef rib and found it "stringy" or hard to chew, it’s not because you bought bad meat. It’s because you missed the Thermal Transition. Here are the three non-negotiables for a world-class "Platrib":

1. The 160°F (71°C) "Melting Point"

Beef ribs are packed with Type I Collagen. Unlike a steak, which is tender at $55°C$, collagen doesn't even begin to break down until it hits the 70°C mark. This is "The Stall." If you rush the heat here, the muscle fibers tighten and squeeze out all the moisture. You have to stay patient at 110°C pit temp to allow that collagen to transform into Gelatin.

2. Bark Architecture (The 16-Mesh Secret)

Ever wonder why pro BBQ has that dark, "craggy" crust? It’s not burnt; it’s the Maillard Reaction combined with pepper granulation. Using standard table pepper is a mistake—it’s too fine. We use 16-Mesh Coarse Black Pepper. These larger grains create "turbulence" in the airflow, allowing smoke particles to stick to the meat. No coarse pepper = no authentic Texas bark.

3. The "Rest" is a Chemical Process

Slicing a rib the moment it comes off the coals is the fastest way to ruin a 9-hour cook. At 95°C, the internal juices are highly pressurized. A 2-hour controlled rest in an insulated cooler allows those juices to thicken and redistribute. This is how you get a rib that stays glistening wet on the cutting board instead of a puddle of liquid and dry meat.

9

0 comments

powered by

skool.com/bbq-beer-and-whiskey-9787

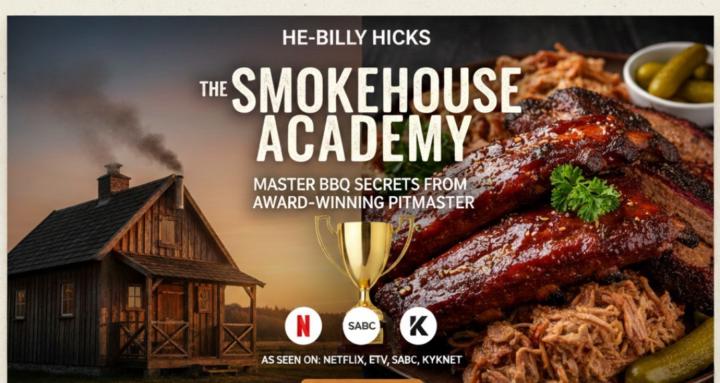

Award-winning pitmaster teaching BBQ, craft beer & whiskey-making. Join He-Billy Hicks' community of makers. Level up your craft. As seen on tv

Suggested communities

Powered by