Activity

Mon

Wed

Fri

Sun

Feb

Mar

Apr

May

Jun

Jul

Aug

Sep

Oct

Nov

Dec

Jan

What is this?

Less

More

Owned by Dallas

Free community for business owners who want to simplify compliance, reduce risk exposure, and protect their profits. No BS. Pure strategy.

Memberships

6 contributions to Risk Management Made Simple

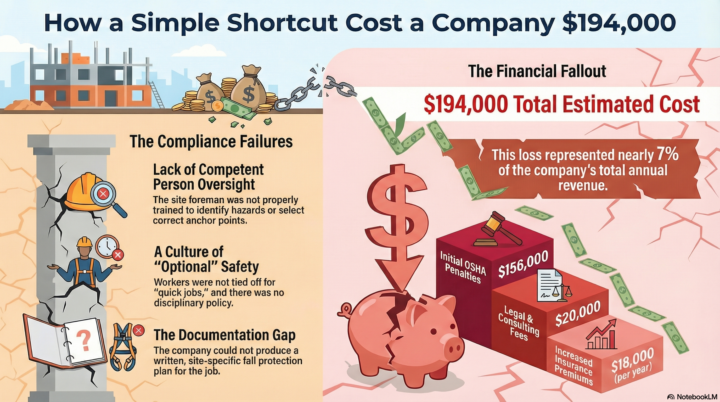

How a Harness Mistake Cost a Company $194,000

This involves a mid-sized commercial contractor operating in the Texas market. They were a solid business: $2.8 million in annual revenue, 12 full-time employees, and a generally good reputation. They weren't "bad actors." They bought good equipment, they held weekly safety meetings (mostly verbal), and they cared about their crew. The Incident: An OSHA inspector was driving to another site when he noticed a crew working on a low-slope commercial roof. He pulled over for a "drive-by" inspection—which they are legally allowed to do if they spot a hazard from the public road.He walked onto the site and found three workers on the roof. - Worker A was wearing a harness but wasn't clipped in. - Worker B was clipped in, but his lanyard was attached to a PVC vent pipe (which is absolutely not a rated anchor point). - The Foreman was on the ground. When asked, he couldn't produce a written fall protection plan for the site. What Went Wrong: The owner of this company fell into the classic trap: He thought "owning the gear" was compliance. He assumed that because he bought $300 harnesses, his guys were safe. He was wrong. Issue 1: Lack of Competent Person Oversight - OSHA requires a "Competent Person" to identify hazards and have the authority to stop work. While the foreman was technically in charge, he hadn't been trained on how to calculate fall clearance or select anchor points. He let Worker B tie off to a PVC pipe because he didn't know better. Issue 2: The "Culture of Optional" - Worker A wasn't clipped in because it was "just a quick job." The culture of the company allowed safety to be optional when it was inconvenient. There was no disciplinary program in place for unsafe behavior. Root Cause 3: The Documentation Gap - If it’s not written down, it doesn't exist. The company had no written site-specific fall protection plan. This turned a "Serious" violation into a much harder conversation about negligence. The Outcome: Because the company owned the gear but failed to enforce its use, OSHA leaned hard on them. They cited Willful Violations—the most expensive category—arguing "plain indifference" to the law.

Monday Risk Tip - Fall Protection, and Why It Matters

This week, we're going to hit on OSHA's favorite violation: Fall Protection. The "undisputed champion" for the last 14 years straight, fall protection is one of the most overlooked precaution that OSHA tracks.

1

0

How to Get Maximum Value From This Community (And What's Coming Next Week)

Happy Friday, y'all By now you've heard the mission (education, not gatekeeping), and you understand the structure (Compliance → Workers Comp → Operational Risk). Every week follows the same pattern. Here's what to expect: Monday: Risk Tip Post - One specific problem (not 5), Real data/numbers, Why it matters to YOUR business, What you should know, and a Discussion prompt. Time commitment: 4-5 minutes to read What to do: Read, think about whether it applies to you, answer the discussion question honestly Wednesday: Case Study - A Real scenario (anonymized real business), What went wrong (or what went right), Root causes breakdown, and a Lesson for YOUR business Time commitment: 5-7 minutes to read What to do: Read, compare to your situation, engage in comments with other members Friday: Action + Engagement - You'll get a framework, checklist, or self-assessment you can use, Actionable next steps, and a Discussion prompt with accountability angle Time commitment: 5-10 minutes (depending on if you do the action item) What to do: Download the resource, do the assessment, commit to one action publicly How to Maximize This ✅ DO THIS: - Show up on schedule (Monday/Wednesday/Friday at the times posted) - Engage in discussion (comment with your answer to the prompt) - Do the Friday action item (don't just read it) - Share your obstacles/questions (that's what the community is for) - Hold yourself accountable (public commitment = higher follow-through) ❌ DON'T DO THIS: - Read passively and move on (you'll retain 10% instead of 70%) - DM me asking me to solve your specific situation in 5 minutes (I will, but it's $750/hour consulting—the content is free for a reason) - Skip engagement because you're "shy" (this community thrives on real problems, not lurking) - Wait until Week 12 to implement anything (compounding action beats delayed perfection) On the last Friday of each month, I'll send out Downloadable Resource A template, checklist, or assessment you can actually use (OSHA audit checklist, EMR calculation template, etc.) as an bonus to help you assess your business more.

3

0

The 3 Risk Pillars Every Business Needs To Be Aware Of

When I work with a business, I'm always mapping the same three categories: Pillar 1: Compliance Risk Pillar 2: Workers Compensation Risk Pillar 3: Operational Risk They're not separate problems. They're interconnected. But they require different strategies. 🔍PILLAR 1: COMPLIANCE RISK The Problem: You're not compliant, you get cited, you pay penalties, your insurance goes up. What Most Business Owners Don't Understand: OSHA rewrote their penalty structure in 2025. Small businesses (≤25 employees) can now reduce penalties by 70% if they know the rules, but most business owners don't know the rules exist, so they get hit with a $16,550 penalty when they could've paid $2,400 if they'd known. Real Example: - A smaller manufacturing shop gets cited for fall protection violations - Manager thinks: "We're getting fined $16,550. This is bad." - What they don't know: They qualify for 70% size reduction + 15% quick-fix bonus + 20% clean history credit = 85% total reduction - Actual penalty: ~$2,483 The difference: $14,067 they didn't need to lose. Compliance isn't just about penalties. It's about being audit-ready before inspectors show up, understanding which violations exist in YOUR operation, having a framework to fix them before they become problems, and knowing which compliance areas require expertise vs. which you can DIY These first few weeks, we're breaking down OSHA violations, compliance frameworks, audit systems, and how to self-inspect before the government does. 💔PILLAR 2: WORKERS COMPENSATION RISK The Problem: One bad year of claims tanks your experience mod, and you're overpaying premiums for 3+ years. What Most Business Owners Don't Understand: Your workers' comp premium is NOT just based on your payroll and job classification. It's based on your Experience Modification Rate (EMR), which is calculated from your claim history. One $50,000 claim can increase your premium by 15-25% for multiple years, and three $20,000 claims hurt you more than one $60,000 claim (this is the part that confuses everyone).

Week 0: Why I Built This

Hey, Dallas here. Buckle up, this is a longer one. I'm going to be straight with you: I didn't build this community because I had extra time on my hands. I built it because I'm tired of watching business owners get blindsided. "Dallas, why did my workers' comp bill jump 40%?" "When did you last get hit with an OSHA citation?" "I didn't even know we had that insurance gap until the claim came." "The auditor says I owe $8,000. How is that even legal?" These aren't rare conversations. They're the rule, not the exception. Here's What I've Learned: I've been in the insurance and risk management space for a decade, operating across Iowa and Texas. I've worked with hundreds of business owners—from $1M shops to huge operations, and the pattern is always the same: Most businesses are one OSHA violation, one premium audit, or one worker injury away from a financial crisis they didn't see coming. Not because they're bad operators. Not because they don't care about safety. Because nobody taught them the system. You were taught how to run your business. How to build a team. How to serve clients. How to manage cash flow. Nobody taught you about experience modification rates, OSHA compliance tiers, insurance classification codes, or workers' comp claim management. And the people selling you insurance? They're not incentivized to educate you. They profit from your confusion. So you're left asking Google, hoping Reddit has answers, or paying consultants $15K-$30K just to tell you what you should've known already. That's why I'm here. This is NOT: - Another sales pitch disguised as education - Generic "compliance tips" you could find anywhere - A place where I'm gatekeeping information to sell you later This IS: - A weekly deep-dive into the three areas that destroy businesses: Compliance, Workers Comp, and Operational Risk - Real frameworks, real examples, real actionable strategies - A community of business owners who are done getting surprised - The foundation for you to either DIY or make smart decisions about when to hire an expert

2

0

1-6 of 6

@dallas-downey-7545

Risk advisor helping business owners protect profits, reduce risk, and simplify compliance through smart, practical strategies.

Active 6h ago

Joined Aug 24, 2025