Write something

Welcome New Members

Feel free to look around, take a course or two, or ask questions. I'm in the studio working on more designs, patterns, and courses. I'll check in again soon!

0

0

⚖️ Day 5: Taming the Tension

The Great Tug-of-War If your stitches look loopy on the bottom, or your fabric is puckering like a raisin, your tension is out of balance. Think of your sewing machine as a game of Tug-of-War: the top thread and the bobbin thread need to pull with the exact same strength to meet perfectly in the middle of your fabric. 1. The "Bird’s Nest" (Loops on the Bottom) The Myth: "My bobbin is messed up!" The Reality: It’s actually your top thread. If you see a mess of loops underneath the fabric, the top thread isn't being held tight enough. It’s falling through the hole too fast. 2. The Pucker (Tight Stitches) If your fabric is gathering or "scrunching" as you sew, your tension is too tight. The threads are pulling so hard they’re crushing the fabric fibers. The "90% Rule" Fix: Before you touch those tension dials, do this: Rethread with the Foot UP: This is the #1 mistake! When the presser foot is down, the tension discs are closed. If you thread while the foot is down, the thread can't get inside the discs. Always lift the presser foot, rethread the top, then rethread the bobbin. 9 times out of 10, this fixes the problem! 💡 Pro Tip: The Two-Color Test If you’re really struggling to see what’s wrong, use a red thread on top and a blue thread in the bobbin. Sew a straight line on a scrap of white fabric. If you see red dots on the bottom, the top is too loose. If you see blue dots on the top, the top is too tight. Designer Note: "Don’t let a 'bird's nest' ruin your creative flow. Most 'machine problems' are actually just 'threading problems.' Take a breath, unthread, and start fresh." — Leah B.

🪡 Day 3: Needle Knowledge

Small Tool, Big Impact Think of your sewing machine needle like a high-performance tire on a car. If the tires are worn out or the wrong type for the road, the ride won't be smooth! 1. The "Golden Rule" of Timing Most designers wait until a needle breaks to change it. Don't do that! * The Rule: Change your needle after every 8 hours of sewing or at the start of every new project. A dull needle "punches" through fabric instead of piercing it. 2. Match the Needle to the Fabric Different fabrics require different points to ensure the thread passes through cleanly: Universal: Best for general woven fabrics (like cotton). Ballpoint/Stretch: Essential for knits and jerseys. The rounded tip slides between the fibers instead of cutting them (preventing holes!). Microtex/Sharp: Very slim and sharp. Use these for silks, microfibers, or when topstitching for that extra-crisp look. 3. Understanding the Numbers You’ll see numbers like 70/10 or 90/14 on the pack. Small Number (70/10): For lightweight, delicate fabrics (Chiffon, Silk). Large Number (90/14 or 100/16): For heavy fabrics (Denim, Canvas, Upholstery). 💡 Pro Tip: The Sound Test Listen to your machine. If you hear a rhythmic "thump-thump-thump" as the needle hits the fabric, it’s likely dull or too small for the material. Swap it out immediately! Designer Note: "Your needle is the frontline of your design. A fresh, correct needle is the cheapest way to instantly upgrade your stitch quality." — Leah B.

1-30 of 30

powered by

skool.com/krewe-of-designers-5161

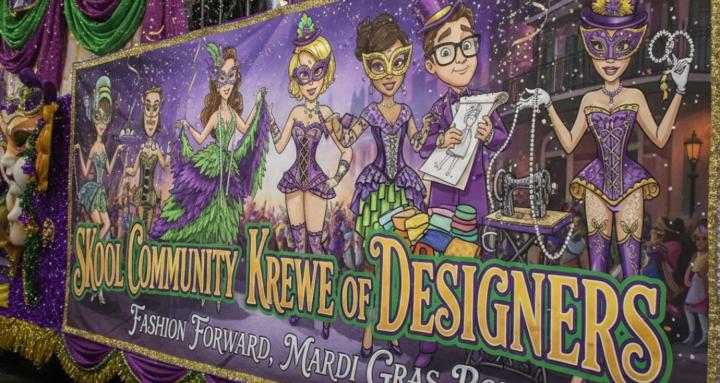

Louisiana based sewing community for aspiring and growing Indie Fashion Designers. I offer everything from basic dress making to embroidery.

Suggested communities

Powered by